If you’ve ever wondered how things move in a straight line, you’re thinking about linear motion. Linear motion is a type of movement that goes in a straight line, and it’s essential in so many things we use every day. Here’s why this is so important in our daily lives.

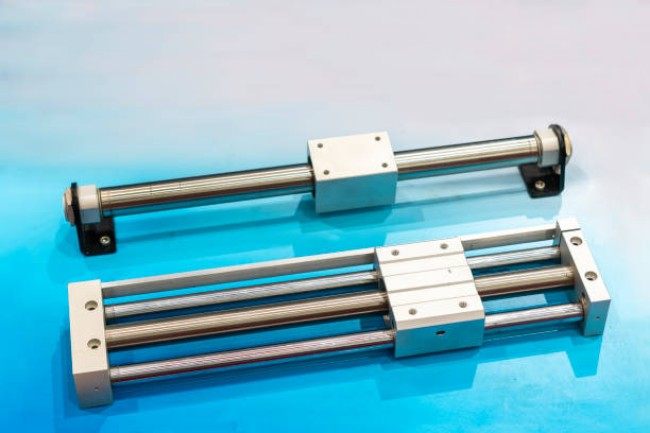

What’s a Linear Actuator?

A linear actuator might sound like a fancy term, but it’s a pretty straightforward thing. Think of it as a tool that takes energy and turns it into straight-line movement. Imagine pushing a book across a table.

Your hand is like the linear actuator, and the book moves in a linear (straight) path. Linear actuators are like the muscles of machines. They help them move things back and forth or up and down with precision.

Types of Linear Actuators

Linear actuators come in different shapes and sizes, and they’re used in various applications. Here are a few common types:

- Electric Linear Actuators: These incorporate electric motors and electronic control units (ECUs) as their primary components. The motor transforms electrical energy into mechanical motion, while the ECU precisely regulates the actuator’s movement, making them ideal for applications requiring fine control, such as adjusting car seats or operating robotics.

- Hydraulic Linear Actuators: These are equipped with several key components to efficiently convert pressurized fluid into motion, including hydraulic hoses, pumps, and valves. The hoses transport the fluid that activates the actuator, which is crucial for operating heavy machinery like bulldozers and excavators. Pumps generate the necessary pressure, while valves control the flow, enabling precise movement and powerful force application.

- Pneumatic Linear Actuators: They rely on air compressors and valves to function effectively. The compressor generates the compressed air that drives the actuator, and the valves manage the airflow, ensuring precise and rapid movement essential for manufacturing and automation processes, where accuracy and speed are critical.

- Mechanical Linear Actuators: These use good old-fashioned mechanics, like gears and screws, to make things move. They’re common in manual adjustments like the height of a dentist’s chair or the steering column in your car.

How Linear Actuators Work

So, how do linear actuators work their magic? Most linear actuators have a few essential components:

- Actuator body: This is the outer casing that protects the inner parts of the actuator.

- Motor: In electric linear actuators, this is usually an electric motor that provides the power needed for movement.

- Screw or rod: This part moves and pushes or pulls the load. It’s like the arm of the actuator.

- Gearbox: In some actuators, a gearbox is used to increase the force and decrease the speed of the movement. It’s like the actuator’s muscles, making it stronger.

- Limit switches: These are like stop signs for the actuator. They tell it when to stop moving in one direction and start moving in the other.

- Control system: This is the brain of the actuator, which manages when and how the actuator should move. It can be controlled manually with buttons or automatically by a computer.

When you want to move something using a linear actuator, the motor gets powered up. From there, it starts turning the screw or rod. As the screw or rod rotates, it pushes or pulls the load, causing it to move in a straight line.

Common Applications of Linear Actuators

Linear actuators are all around us, often working behind the scenes to make our lives easier. Here are some common applications where you’ll find these essential devices at work:

- Automotive Adjustments: Linear actuators help adjust your car seats, move the windows up and down, and control the position of the sunroof.

- Home Automation: In your home, linear actuators can be found in things like motorized blinds, adjustable beds, and dishwashers to help with the soap dispenser.

- Industrial Machinery: Linear actuators are used in manufacturing to move things precisely, like conveyor belts or assembly line machines.

- Medical Equipment: In the medical field, linear actuators are used to adjust the height of hospital beds, move X-ray machines, and control the position of dental chairs.

- Farming and Agriculture: Linear actuators are essential in farming equipment, helping with tasks like adjusting the height of plows and controlling the flow of seeds or fertilizer.

- Aerospace: They’re used in aircraft to control various functions, such as adjusting flaps or landing gear.

- Robotics: Robots use linear actuators to move their arms and legs, allowing them to perform tasks precisely.

Choosing the Right Linear Actuator

If you ever need to pick the right linear actuator for a project, there are a few things to consider:

- Load capacity: How heavy is the object you want to move? Make sure your actuator can handle it without straining.

- Speed: Depending on your application, you might need a faster or slower actuator. Some can move quickly, while others are designed for slow and precise movements.

- Stroke length: This is how far the actuator can extend or retract. Make sure it’s long enough for your needs.

- Mounting: Consider how you’ll attach the actuator to your project. There are different mounting options, so choose the one that suits your application.

- Control: Think about how you’ll control the actuator. Do you need a manual switch, a remote control, or something more automated?

Move Forward With Linear Actuators

Linear actuators may not be something you think about daily, but they play a significant role in things moving smoothly and precisely. From adjusting your car seat to powering industrial machines, linear actuators are everywhere.

Whether you’re a budding engineer or curious about how things move, mastering motion with linear actuators is an exciting thing to know more about.